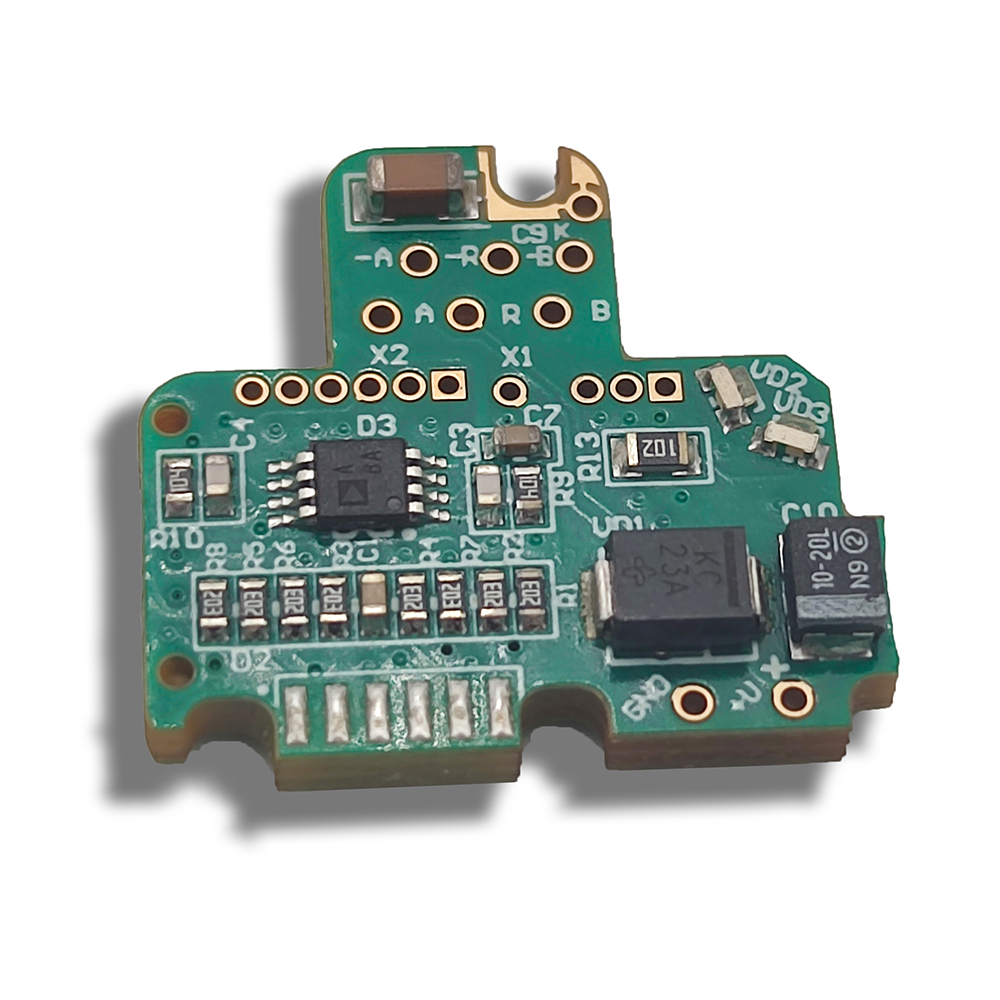

SMT 6L ENIG PCBA Module

Manufacturing info

| Model No. | PCB-A21 |

| Assembly method | SMT |

| Transport package | Anti-static Packaging |

| Certification | UL, ISO9001&14001, SGS, RoHS, Ts16949 |

| Definitions | IPC Class2 |

| Minimum Space/Line | 0.075mm/3mil |

| Application | Communication |

| Origin | Made in China |

| Production Capacity | 720,000 M2/Year |

Product Description

This module is a 6-layer printed circuit board (PCB) with a dimension of 22.54mm*23.74mm, and a board thickness of 1.6mm. It is made from high-quality FR4 base material, which is strong and durable, making it suitable for use in a wide range of applications.

The surface finish on this PCB is ENIG, which stands for Electroless Nickel Immersion Gold. This finish provides excellent protection against oxidation and corrosion, making it ideal for use in environments where moisture and humidity are present. The copper thickness of this PCB is 1.0oz, which ensures excellent electrical conductivity and performance.

The assembly method used for this PCB is SMT, which stands for Surface Mount Technology. This method involves mounting electronic components directly onto the surface of the PCB, resulting in a more compact and efficient design. With SMT, components can be mounted on both sides of the board, allowing for more complex designs.

To ensure the highest level of protection during transportation, we use anti-static packaging, which provides excellent protection against electrostatic discharge, a common problem during the transportation and storage of electronic components.

Our 6L ENIG PCBA Module, Model No. PCB-A21 is perfect for use in a wide range of electronic devices, from consumer electronics to industrial machinery. It is ideal for applications that require high-performance, durability, and reliability.

In addition to PCB Assembly services, we also offer a wide range of other products and services, including PCB design, PCB manufacturing, and PCB testing. With our comprehensive range of services, we are the one-stop-shop for all your PCB needs. If you need PCB testing, please send me your testing guide as well.

Whether you need a standard product or a custom design, we are here to help. Contact us today to learn more about our PCB Assembly services and how we can help you meet your electronic design and manufacturing needs.We believe that the ultimate application of the product depends on your needs.

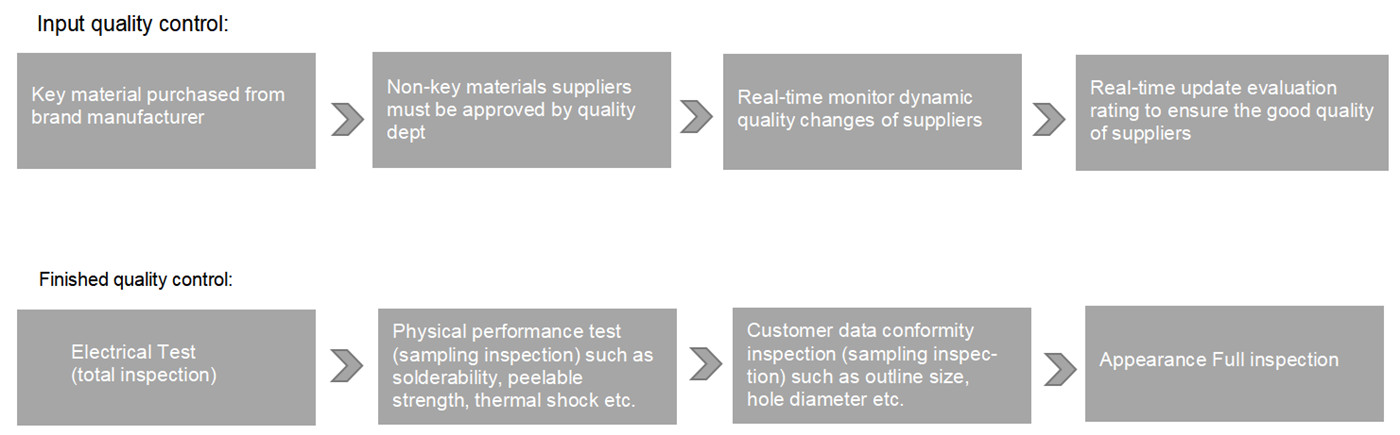

Quality Control

Certificate

FAQ

PCBA is used in the manufacturing of various electronic devices, including smartphones, computers, and medical equipment.

Yes, PCBs can be assembled by hand, but it is a time-consuming and error-prone process. Automated assembly using pick-and-place machines is the preferred method for most PCBs.

A PCB is a board with copper tracks and pads that connect electronic components. PCBA refers to the assembly of components onto a PCB to create a functioning electronic device.

Solder paste is used to temporarily hold electronic components in place before they are permanently attached to the PCB during the reflow soldering process.

PCBs are tested using various methods, including visual inspection, functional testing, and automated testing equipment.

A: We suggest using DHL, UPS, FedEx, and TNT forwarders for reliable and efficient deliveries.

A: Our shipping fees are based on the express company's rules and are provided with no additional charges.

A: Our product pricing mechanism is subject to change based on market factors and supply. Please send an inquiry, and we will provide you with an updated price list.

A: We accept multiple payment options, including T/T, PayPal, and Western Union.