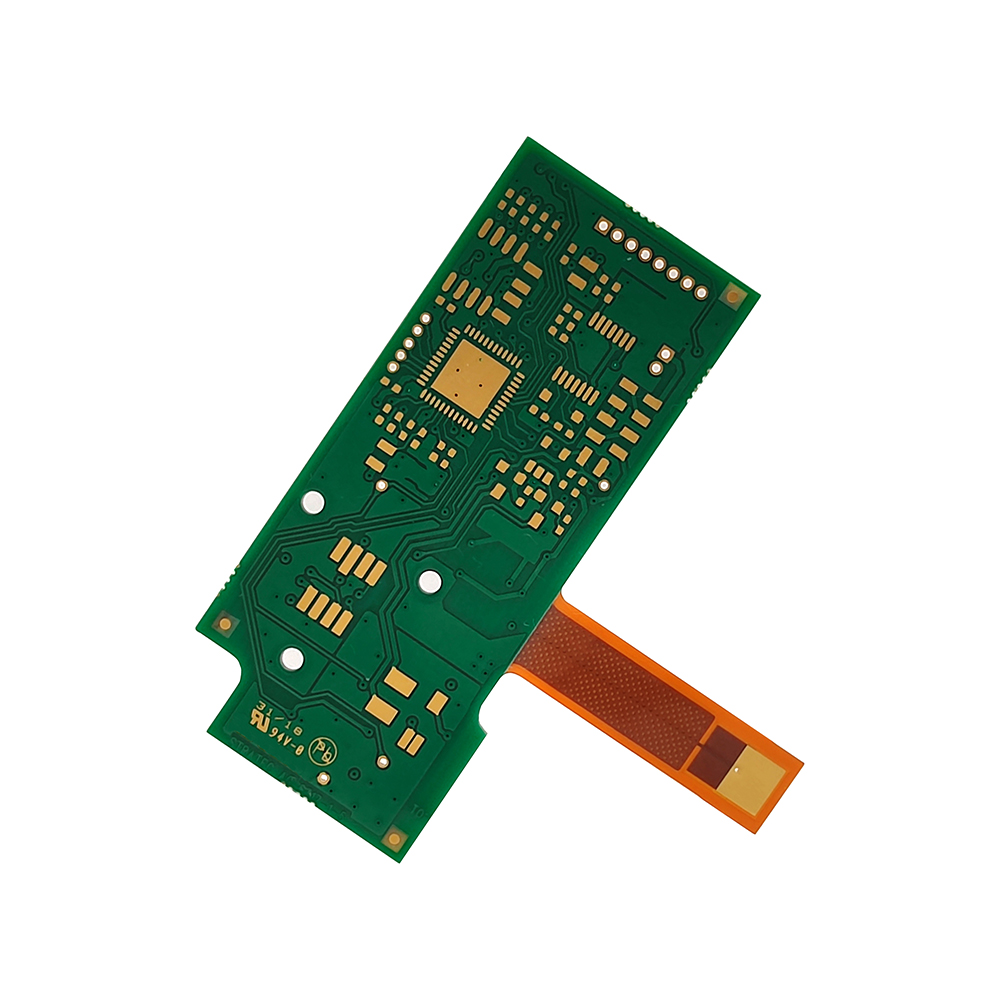

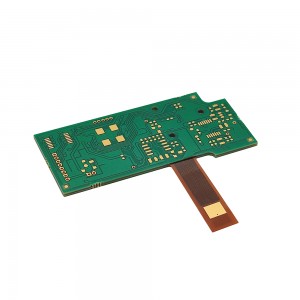

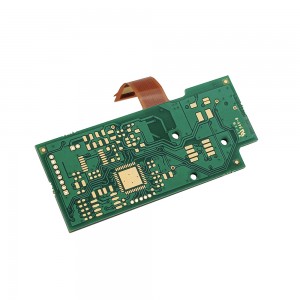

OEM 4 Layers Rigid-Flex ENIG Circuit Board

Manufacturing info

| Model No. | PCB-A18 |

| Transport package | Vacuum Packing |

| Certification | UL, ISO9001&14001, SGS, RoHS, Ts16949 |

| Definitions | IPC Class2 |

| Minimum Space/Line | 0.075mm/3mil |

| HS Code | 85340090 |

| Origin | Made in China |

| Production Capacity | 720,000 M2/Year |

Product Description

Welcome to our website, where we introduce our latest product - the PCB-A18 4 Layers Rigid-Flex ENIG PCB. Our PCB-A18 is a cutting-edge 4-layer rigid-flex printed circuit board with dimensions of 60mm*52.12mm, constructed with high-quality FR4 and PI base materials and a board thickness of 1.7mm.

Our PCB-A18 Rigid-Flex PCB is a unique type of printed circuit board that combines the advantages of both rigid and flexible PCBs. The rigid part provides mechanical stability, while the flexible part allows for greater flexibility in design and space-saving. This makes the PCB-A18 ideal for high-performance applications where size and weight are critical factors.

At the heart of this product is the Electroless Nickel Immersion Gold (ENIG) surface finish, which ensures excellent conductivity, corrosion resistance, and a longer lifespan. Our PCB-A18 also features Filled Vias, which enhances the mechanical strength of the board and provides better heat dissipation.

The PCB-A18 Rigid-Flex ENIG PCB is designed and manufactured in compliance with IPC Class2, ensuring the highest standards of quality and performance. Our product is also certified for its reliability and safety, making it the ideal solution for high-performance applications.

Our product features a solder mask color of Green, which provides an aesthetic appeal to the board. The Legend color is blank, providing a clean and sleek look.

Trust our PCB-A18 Rigid-Flex ENIG PCB for your next project, and experience the difference that quality and performance make.

FAQ

A: A rigid-flex PCB is a combination of both rigid and flexible materials in a single board, making it more versatile and able to bend without breaking. This is different from a traditional PCB, which is made entirely of rigid materials.

Q2:What are the advantages of using a rigid-flex PCB?

A: Rigid-flex PCBs are commonly used in applications that require high durability, reliability, and flexibility, such as aerospace, medical devices, and military electronics.

A: Yes, rigid-flex PCBs are designed to withstand harsh environments and high-stress applications, making them ideal for use in aerospace and military applications.

A: Rigid-flex PCBs are manufactured using a combination of rigid and flexible materials that are bonded together using a specialized process. Key considerations during the design phase include the location and type of bend points, the thickness and type of materials used, and the required number of layers.

A: Some limitations and drawbacks of rigid-flex PCBs include higher manufacturing costs, longer lead times, and increased design complexity.

A: The choice of materials for a rigid-flex PCB depends on factors such as the desired level of flexibility, the required number of layers, and the operating environment. Common materials include polyimide, FR4, and copper.

A: Yes, SMT can be used with rigid-flex PCBs, although the design must take into account the potential for stress on the components during bending.

A: Testing and inspection of rigid-flex PCBs require specialized equipment and techniques that take into account the flexible components. This may include bend testing, X-ray inspection, and high-frequency testing.

A: We offer several payment options, including T/T, PayPal, and Western Union.