ABIS Circuits: PCB boards play a crucial role in electronic devices by connecting and supporting various components within a circuit. In recent years, the PCB industry has experienced rapid growth and innovation driven by the demand for smaller, faster, and more efficient devices across different sectors. This article explores some significant trends and challenges that are currently influencing the PCB industry.

Biodegradable PCBs

An emerging trend in the PCB industry is the development of biodegradable PCBs, aiming to reduce the environmental impact of electronic waste. The United Nations reports that approximately 50 million tons of e-waste are generated annually, with only 20% being properly recycled. PCBs are often a significant part of this issue, as some materials used in PCBs do not degrade well, leading to pollution in landfills and surrounding soil and water.

Biodegradable PCBs are made from organic materials that can naturally decompose or be composted after use. Examples of biodegradable PCB materials include paper, cellulose, silk, and starch. These materials offer advantages such as low cost, lightweight, flexibility, and renewability. However, they also have limitations, such as reduced durability, reliability, and performance compared to conventional PCB materials. Currently, biodegradable PCBs are more suitable for low-power and disposable applications like sensors, RFID tags, and medical devices.

High-Density Interconnect (HDI) PCBs

Another influential trend in the PCB industry is the increasing demand for high-density interconnect (HDI) PCBs, which enable faster and more compact interconnections between devices. HDI PCBs feature finer lines and spaces, smaller vias and capture pads, and higher connection pad density compared to traditional PCBs. The adoption of HDI PCBs brings several benefits, including improved electrical performance, reduced signal loss and cross-talk, lower power consumption, higher component density, and smaller board size.

HDI PCBs find extensive use in applications requiring high-speed data transmission and processing, such as smartphones, tablets, laptops, cameras, gaming consoles, medical devices, and aerospace and defense systems. According to a report by Mordor Intelligence, the HDI PCB market is expected to grow at a compound annual growth rate (CAGR) of 12.8% from 2021 to 2026. The growth drivers for this market include the rising adoption of 5G technology, the increasing demand for wearable devices, and advancements in miniaturization technology.

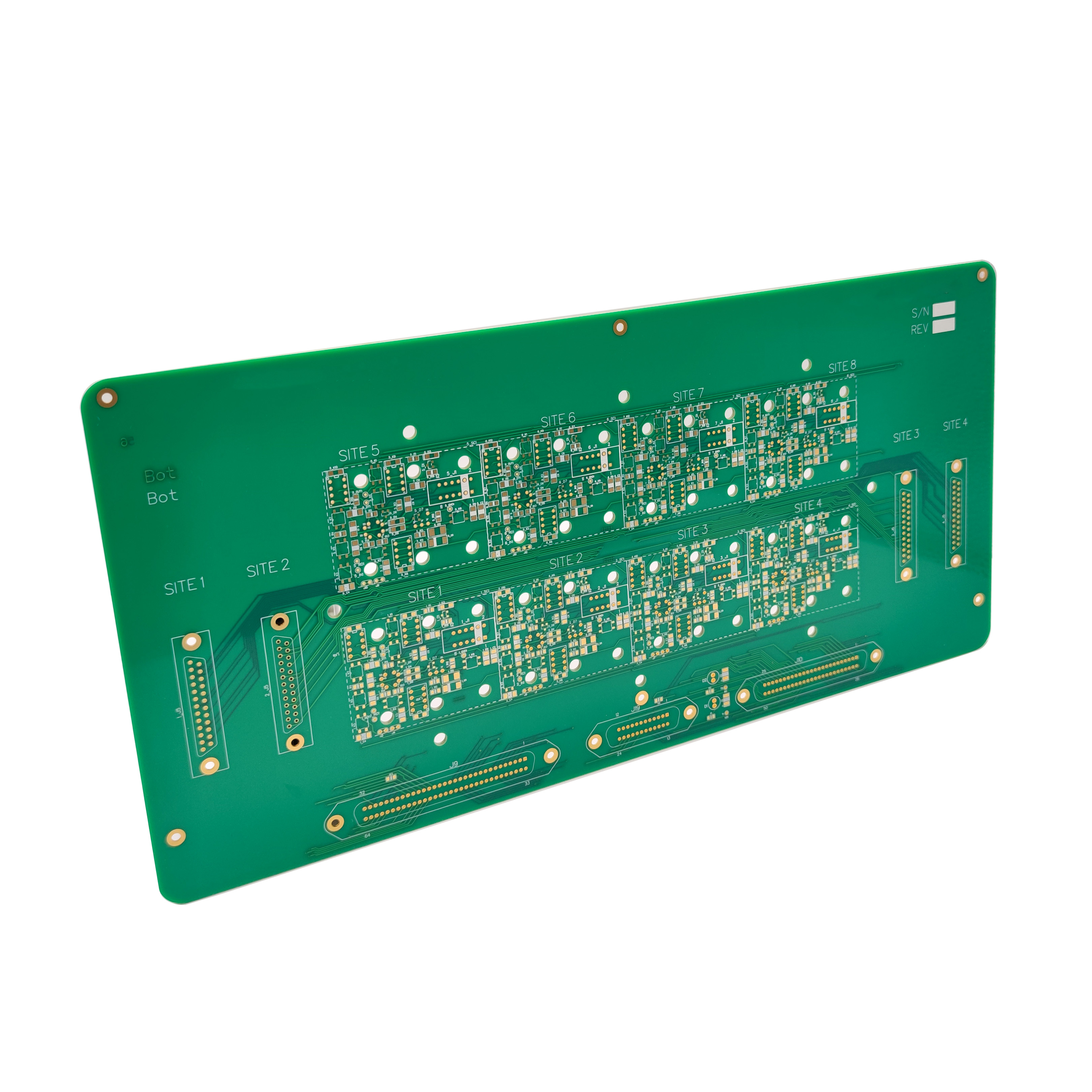

- Model NO.:PCB-A37

- Layer:6L

- Dimension:120*63mm

- Base Material:FR4

- Board Thickness:3.2mm

- Surface Funish:ENIG

- Copper Thickness:2.0oz

- Solder mask color:Green

- Legend color:White

- Definitions:IPC Class2

Flexible PCBs

Flex PCBs are gaining popularity in the industry as another type of PCB. They are made from flexible materials that can bend or fold into various shapes and configurations. Flex PCBs offer several advantages over rigid PCBs, including improved reliability, reduced weight and size, better heat dissipation, enhanced design freedom, and easier installation and maintenance.

Flex PCBs are ideal for applications that require conformability, mobility, or durability. Some examples of flex PCB applications are smartwatches, fitness trackers, headphones, cameras, medical implants, automotive displays, and military equipment. According to a report by Grand View Research, the global flex PCB market size was valued at USD 16.51 billion in 2020 and is expected to grow at a CAGR of 11.6% from 2021 to 2028. The growth factors for this market include the increasing demand for consumer electronics, the rising adoption of IoT devices, and the growing need for compact and lightweight devices.

Conclusion

The PCB industry is undergoing significant changes and facing challenges as it strives to meet the evolving needs and expectations of customers and end-users. Key trends shaping the industry include the development of biodegradable PCBs, the increasing demand for HDI PCBs, and the popularity of flexible PCBs. These trends reflect the demand for more sustainable, efficient, flexible, reliable, and fast PCB

Post time: Jun-28-2023