4 Layers Immersion Silver Blue PCB

Manufacturing info

| Model No. | PCB-A22 |

| Transport package | Vacuum Packing |

| Certification | UL, ISO9001&14001, SGS, RoHS, Ts16949 |

| Definitions | IPC Class2 |

| Minimum Space/Line | 0.075mm/3mil |

| HS Code | 85340090 |

| Origin | Made in China |

| Production Capacity | 720,000 M2/Year |

Product Description

Introducing the 4 Layers Immersion Silver Blue PCB, model number PCB-A22, from our trusted PCB OEM manufacturer in Shenzhen, China. This high-quality PCB is manufactured to provide top-notch performance for all your electronic needs.

Constructed with FR4 base material and a board thickness of 1.6mm, this 4-layer PCB measures 80mm by 120mm. The copper thickness is 2.0oz, making it an ideal choice for complex and high-frequency circuits. The surface finish is immersion silver, which is a popular choice for its excellent conductivity and solderability.

Compared to other surface finishes, such as HASL-LF and immersion tin, immersion silver provides several benefits. It offers a flat and uniform surface, ensuring consistent thickness and excellent planarity. This surface finish is also cost-effective, making it a preferred choice for many manufacturers. Furthermore, immersion silver provides better solderability, making it easy to solder components. The board is designed to meet IPC Class2 standards, ensuring reliable and durable performance.

The 4 Layers Immersion Silver Blue PCB comes with vacuum packaging, ensuring that it arrives at your doorstep in perfect condition. It is certified with UL, ISO9001&14001, SGS, RoHS, and Ts16949, ensuring that it meets international quality and safety standards.

Overall, the 4 Layers Immersion Silver Blue PCB is an excellent choice for all your electronic needs, providing high performance, reliability, and cost-effectiveness. Order now and take advantage of our competitive pricing and fast delivery.

Technical & Capability

| ITEM | CAPABILITY | ITEM | CAPABILITY |

| Layers | 1-20L | Thicker Copper | 1-6OZ |

| Products Type | HF(High-frequency) &(Radio Frequency)board, Imedance controlled board, HDIboard, BGA & Fine Pitch board | Solder Mask | Nanya & Taiyo; LRI & Matt Red. green,yellow, white, blue, black |

| Base material | FR4(Shengyi China,ITEQ, KB A+,HZ),HITG,FrO6,Rogers,Taconic,Argon,Nalco lsola and so on | Finished Surface | Conventional HASL,Lead-free HASL,FlashGold,ENIG (lmmersion Gold) OSP (Entek),lmmersion TiN, lmmersion Silver,Hard Gold |

| Selective Surface treatment | ENIG(immersion Gold) + OSP ,ENIG(immersion Gold) + Gold Finger, Flash Gold Finger, immersionSlive + Gold Finger, Immersion Tin + Gold Finger | ||

| Technical Specification | Minimum line width/gap: 3.5/4mil (laser dril) Minimum hole size: 0.15 mm(mechanical drill/4 mill laser drill) Minimum Annular Ring: 4mil Max Copper thickness: 6Oz Max Production size: 600x1200mm Board Thickness: D/S: 0.2-70mm,Mulltilayers: 0.40-7.Omm Min Solder Mask Bridge: ≥0.08mm Aspect ratio: 15:1 Plugging vias capability: 0.2-0.8mm |

||

| Tolerance | Plated holes Tolerance : ±0.08mm(min±0.05) Non-plated hole tolerance: ±O.05min(min+O/-005mm or +0.05/Omm) Outline Tolerance: ±0.15min(min±0.10mm) Functional test: lnsulating resistance: 50 ohms (normality) Peel off strength: 14N/mm Thermal Stress test: 265C.20 seconds Solder mask hardness: 6H E-test voltage: 50ov±15/-0V 3os Warp and Twist: 0.7%( semiconductor test board 0.3%) |

||

Q/T Lead Time

| Category | Quickest Lead Time | Normal Lead Time |

| Double-sided | 24hrs | 120hrs |

| 4 Layers | 48hrs | 172hrs |

| 6 Layers | 72hrs | 192hrs |

| 8 Layers | 96hrs | 212hrs |

| 10 Layers | 120hrs | 268hrs |

| 12 Layers | 120hrs | 280hrs |

| 14 Layers | 144hrs | 292hrs |

| 16-20 Layers | Depends on the specific requirements | |

| Above 20 Layers | Depends on the specific requirements | |

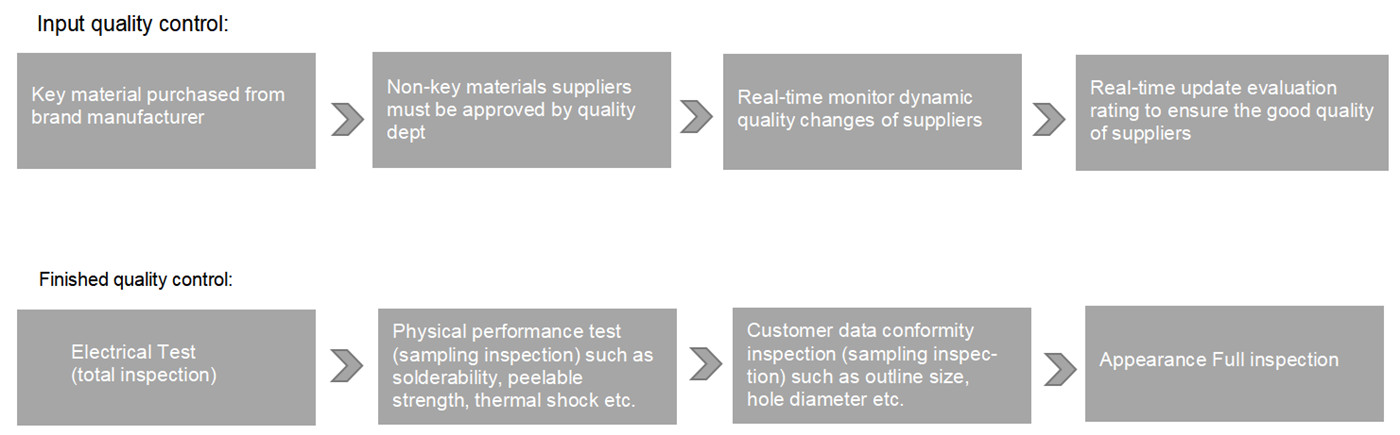

Quality Control

FAQ

A: Our standard practice is to provide a quotation within one hour of receiving your inquiry. In case of urgent requirements, please call us or mention it in your email.

A: The availability of free samples depends on the order quantity. Please contact us for more information.

A: The availability of free samples depends on the order quantity. Please contact us for more information.

A: Typically, it takes 2-3 days to produce samples. The lead time for mass production depends on the order quantity and the current season.

A: Please provide us with detailed information on your inquiry, including the Item Number, Quantity, Quality Requirements, Logo, Payment Terms, Transport Method, and Delivery Location. We will provide you with an accurate quotation as soon as possible.

A: Blue rigid PCBs are used in a wide range of applications, including consumer electronics, industrial control systems, and automotive electronics.

A: Yes, blue rigid PCBs can be customized according to specific requirements, such as size, shape, and number of layers.

A: The lead time for blue rigid PCBs depends on the order quantity and specific requirements, but generally ranges from a few days to several weeks.

A: We recommend using reliable and trusted shipping services such as DHL, UPS, FedEx, and TNT forwarder.

A: We accept payments through T/T, Paypal, Western Union, and other secure methods.